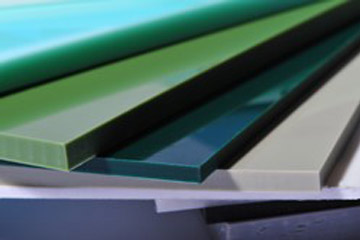

PE (Polyethylene) offers a low weight, good welding, very good impact strength, resistance against cold temperatures, acids and lye's

PP (Polypropylene) can be welded and has really good resistance against acids and lye's while beeing fairly light

Flame retardent plastics after UL94 V0 can save lifes, be milled and offer interesting options...

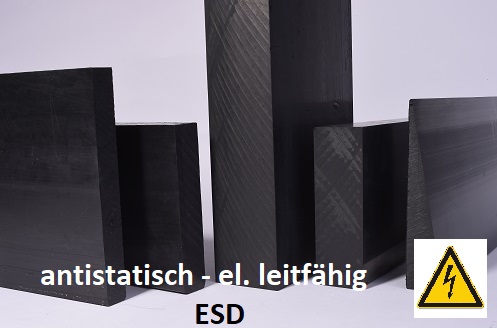

Antistatic and electric conductive plastics have contrary too normal plastics really low surface resistance...

| Application consulting on engineering plastics |

|

Today’s world is reacting faster and faster to new opportunities and every company, if you want to keep up with the competition, you must pick up this pace and recognize potential early enough in purchasing, product development and sales. In the last 50 years, plastic has caught up with, overtaken and now left steel or even other metals and non-metals far behind in terms of output (volume). Compared to the early days of plastic, there is at least one new variation of a plastic almost every day, in metal we would speak of alloy. Would you have thought that

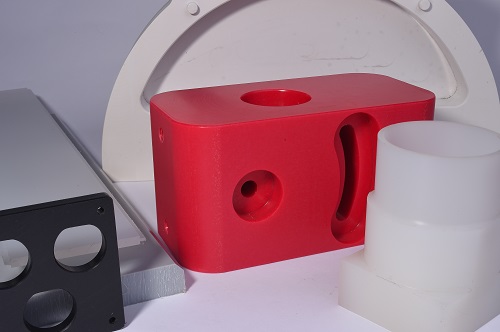

Companies in the steel processing industry in particular certainly have some catching up to do when it comes to researching the possibilities of substituting expensive steel components with less expensive plastic parts. Certainly steel / metal / non-ferrous metals cannot be replaced in many application areas, but if only 10% of your products could be replaced by the obvious advantages of plastics such as much lighter weight, inexpensive material, corrosion protection and easy variation of properties if necessary this would be of great advantage.

Be innovative and don’t just follow your competition. You cannot know all the plastics, but we will be glad to help you with our expert knowledge.

Choose the type of consulting you need from our consulting offer, which includes components such as purchasing optimization, product optimization, product development and much more, and depending on the choice of cooperation can be completely free of charge for you! So why not let us advise you, if it can be without costs for you? |